5 Trends that will Dominate the Manufacturing industry in 2020

Being well into the year, it’s now easier for industry experts to predict the trends that will dominate the manufacturing industry this year and beyond. To stay ahead of competitors, manufacturers must be aware, embrace change, be prepared and leverage all the important transformations that will lead their industry in the coming decade. The coming changes are set to restructure businesses and the modern society. Keep reading as we look at the 5 major innovations that are expected to lead the manufacturing industry in 2020 and beyond.

1. Internet of things (IoT) is transforming all sectors

An increasing number of manufacturers are leveraging the Internet of things. IoT is a system of interconnected computing devices that can be located anywhere in the world. The devices have the abilities to collect and transfer data over wireless networks. It’s possible to control anything and be a part of IoT, from traffic lights to cars and airplanes. This adds some level of digital intelligence to devices and enables them to share data in real-time without human intervention.

Leveraging IoT achieves a number of goals such as an increased efficiency, savings in cost, product innovation and improved safety. According to Forbes and Hitachi, approximately 63% of manufacturers believe that utilising IoT to products will increase profitability over the next 4 years and are prepared to invest US $267 billion in IoT by 2020. They realise that the technology enables them to make informed decisions as it provides vital real-time information. Gartner predicts that there will be 20.4 billion IoT devices used worldwide by 2020. A study by Business Insider Intelligence also shows that the IoT market is expected to increase to over US $ 3 trillion per annum by 2026.

“IoT and predictive analytics are having a major impact on manufacturing, offering exciting new opportunities for connecting operations and transforming business processes” - Michael Strand, Senior Vice President at Hitachi Solutions America.

2. 3D Printing is increasing production efficiency and reducing costs

3D printing is rapidly transforming the manufacturing industry. With companies like Markforged introducing innovative Composite and Metal 3D printers, we see no signs of the trend slowing down. The technology will continue to enhance the production workflows of manufacturers and product designers. It allows them to produce cheaper prototypes at a faster speed compared to traditional manufacturing methods.

The technology is a cost-effective and an efficient way to test and troubleshoot products before mass producing. It also enables companies to produce parts on demand and on-site instead of having to manufacture them in a warehouse and rely on third party suppliers. With industries such as education, aerospace, health, dental and automotive already embracing 3D printing, we will see more sectors in the manufacturing industry catching up and utilising this growing technology next year and beyond.

3. 5G is set to exceed expectations in connection speed and more!

5G, an advanced wireless technology and the next generation from the 3G and 4G network, is one of the most awaited technology trends in recent years. Deployment begun in 2019 with approximately 4 million Koreans having 5G phones as of October and that number is expected to grow to 5 million users at year end. Optus in Australia has begun their 5G rollout and it will only continue to improve as it matures. It will be quicker, more responsive, have greater capacity and more.

Over saturation has been a long issue for cellular communications networks, resulting in inconsistent connectivity. The use of 4G in developed countries is huge and the use of 3G in developing countries yield similar results. Organisations cannot heavily rely on these networks for their operations. However, the new 5G promises to go beyond the expectations of its users. It will provide manufacturing companies with increased connection speeds as they begin to grow their use of centralised tracking, quality inspection and more. With increased coverage, faster and more stable connection, a system of smart manufacturing will be developed.

4. Generative Design exceeds the human mind when it comes to designing

Generative Design is like a CAD (Computer Aided Design) tool. However, unlike the others, the engineer or designer does not have to transcribe their fully formed design idea into the software. They can just input information of their design goals and the tool, using artificial intelligence and cloud computing, generates thousands of solutions and geometries to one design or engineering problem. The results would be impossible for the human mind to envision – or at least at the same speed. The engineer or designer takes the options generated and explores the practicality of the designs.

Manufacturers need to produce large quantities of products to be profitable. This is a major disadvantage for smaller companies without access to production resources. Combining generative design and 3D printing, it’s possible to produce smaller batches of products. The benefits are huge with massive reduction in costs, faster development times and less material consumption.

Click to read Generative Design and its Applications

Click to watch '5 Trends that will Dominate the Manufacturing industry in 2020'

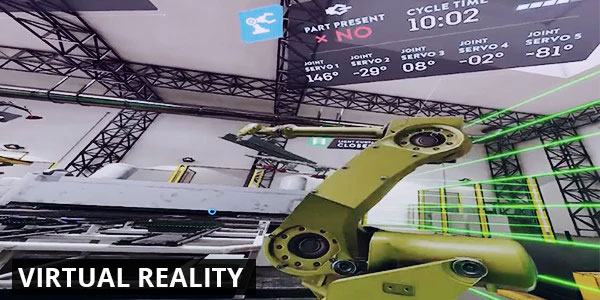

5. Virtual Reality and Augmented Reality are reshaping the world of design.

Immersive and assistive technologies such as Virtual Reality (VR) and Augmented Reality (AR) will continue to create a beneficial collaboration between man and machine. The technology can transform 2D CAD drawings into immersive 3D digital models, providing a unique perspective to the designs. It enables manufacturers and product designers to navigate through data-rich environments and gain interactive real-time experiences, allowing them to make better-informed decisions on their projects. VR and AR can seamlessly collaborate with Computer Aided Design (CAD) programs such as Revit, 3DS Max, Maya, Forge and VRED. Manufacturers and product designers can quickly make modifications and additions to products early in the design process, saving them from future errors before going into the manufacturing stage.