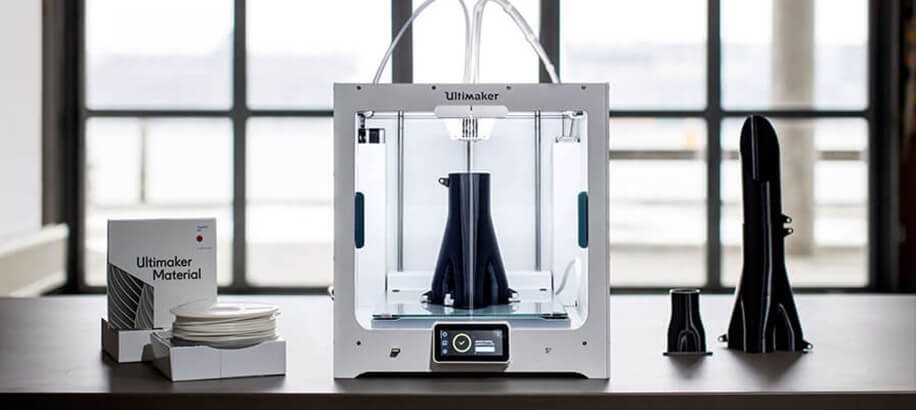

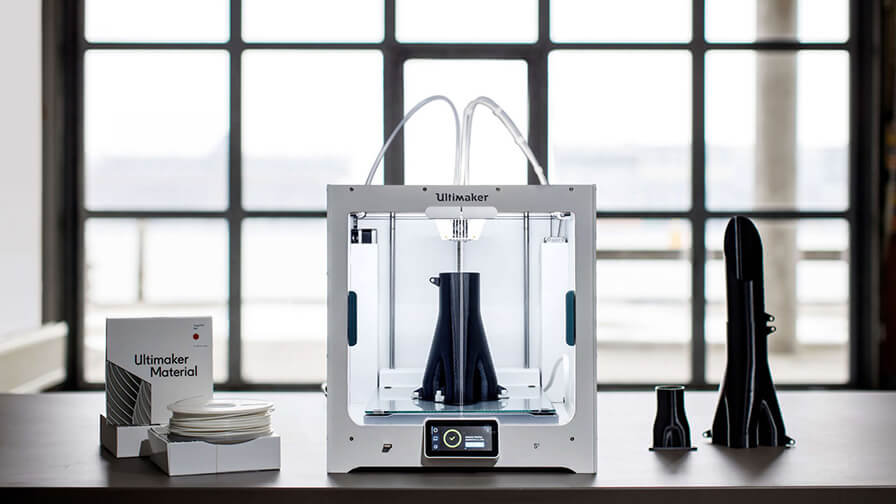

Introducing the Ultimaker S5

This dual-extruder 3D printer is Ultimaker’s most advanced 3D printer to date. It was designed with forward-thinking professionals in mind, such as designers, engineers and architects.

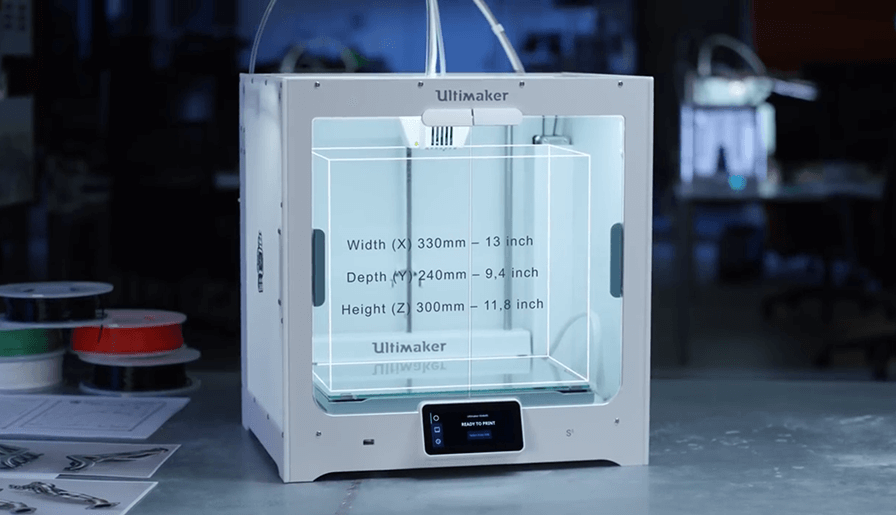

Large Build Volume

The S5 has a large usable build volume measuring 330mm on the X, 240mm on the Y and 300mm on the Z. It’s still compact enough to fit on your desk and looks like hardware that fits in any professional office setting.

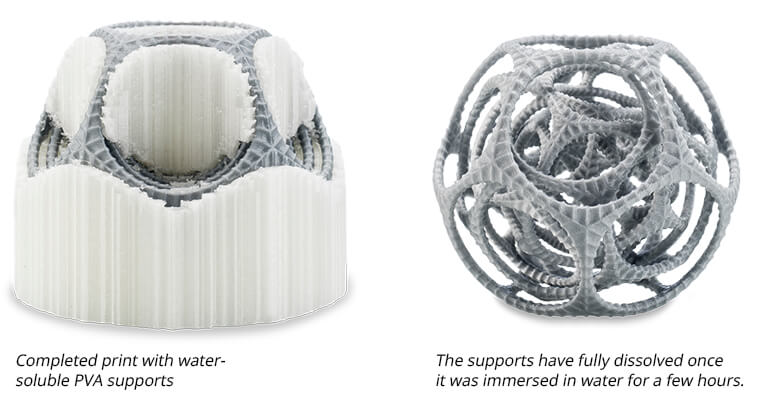

Dual Extruders

Each extruder is fed from a different filament spool, making it possible to switch one of them with a water soluble-filament. The main benefit with this capability is that it allows you to use a water soluble-filament as a support material, giving you the option to print any geometry imaginable. When the print is completed, the object just needs to be immersed in water and the supports will dissolve in a matter of hours.

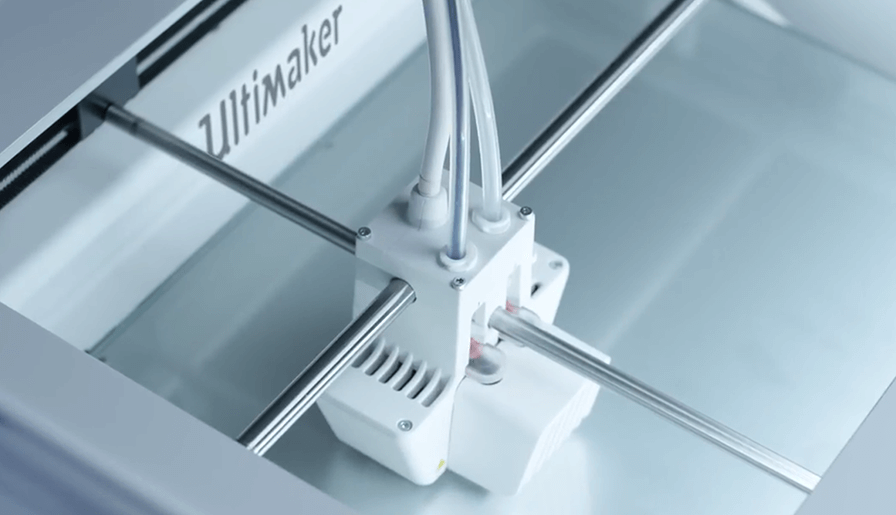

The Carriages Bridge the Top

The extruder unit is attached to two motorised carriages – enabling it’s horizontal motion on the X and Y axis.

Filament Feeder

Two filament feeders are located on back and each side. The feeders include quick release latches and when prompted during setup, a strand of filament needs to be inserted into the bottom with applied pressure until it’s grabbed by the gears and pulled through.

A filament flow sensor is embedded within the feeders that enables the S5 to detect when the filament runs out. This automatically pauses the print job which allows you to insert a new spool and resume the print. This feature is extremely helpful since the S5 is capable of printing such large objects.

Spool Holder and Filament Spools

The S5’s spool holder holding two spools in place. Within the spool holder is a NFC scanner that will automatically detect what Ultimaker filament has been installed.

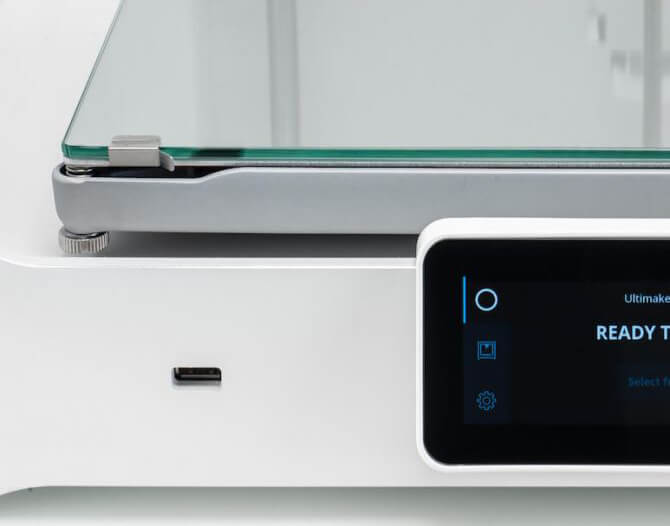

Build Plate

The four metal clips securely hold the removable glass build plate in place. The build plate supporting frame has also been redesigned to give a ridged build platform.

Back

On the lower back of the S5, there are two cooling fans on each side, an Ethernet port, a power-plug jack and a port labelled “UMB Out” – with it’s purpose being to connect future hardware add-ons. A similar port is used to plug in the white cable which supplies NFC connectivity to a spot on the spool feed. This enables the S5 to identify the filament type and colour in the company’s “smart” filament spools.

Touch Panel

The printer has a full colour touchscreen display integrated into the front that allows you to explore menus and select options similar to a smart phone. The display provides detailed information such as loaded materials, print cores and the temperatures of the build plate and nozzle, to update you on the job in progress. You can also access settings and change flow rates while its printing.

Open Top

While the printer is equipped with double glass doors on the front that helps keep the build chamber enclosed, the top includes an open-frame.

Front USB Port

A USB Type-A port is integrated on the front of the S5 for easy accessibility. A USB Flash Drive can be plugged in which enables you to print directly from it with the assistance of the touch panel.

The Print Quality

Not only is it possible to print anything from large to smaller complex parts, the print quality cannot be faulted. The S5 performed well in printing the larger manifold and the intricate brace shown below.

Reference:

PCMag Australia. 2019. Ultimaker S5 - PCMag Australia.

Available at: https://au.pcmag.com/printers/60455/ultimaker-s5.

Ultimaker.com. 2019. Ultimaker S5: Reliability at scale .

Available at: https://ultimaker.com/en/products/ultimaker-s5.