Markforged Composite 3D Printer Comparison

By Damien Jovica | A2K Technologies Industry Expert

Which 3D Printer – Desktop or Industrial?

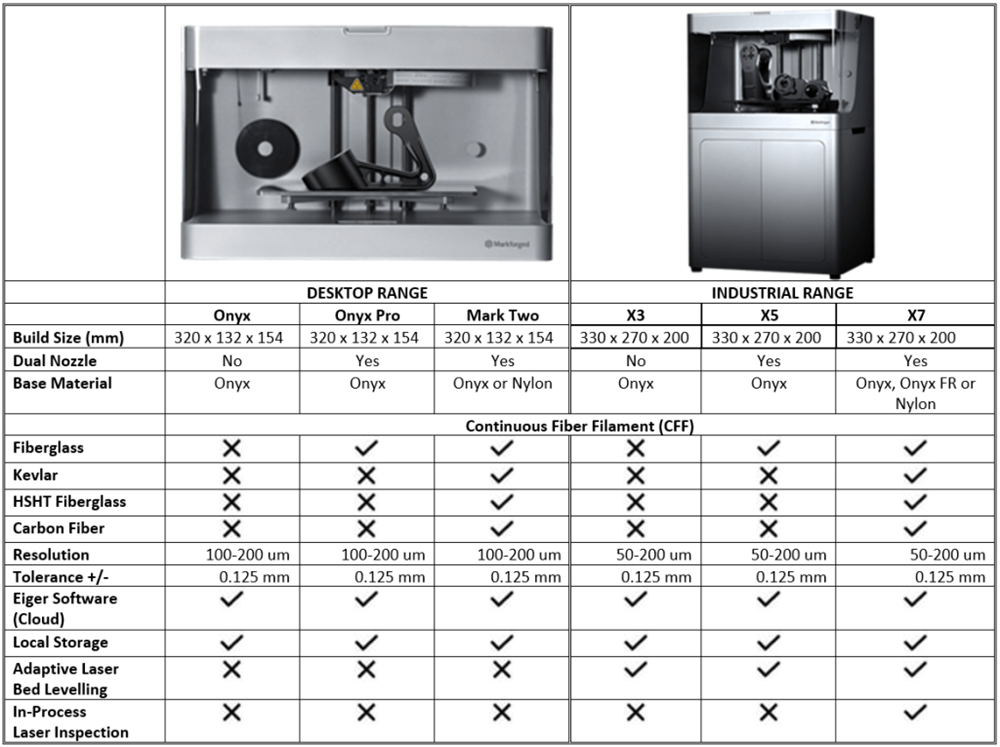

When it comes to choosing which Markforged composite 3D printer will suit your requirements and budget, the choices are Desktop and Industrial. On paper, the printers are very similar in features and deciding which one to choose can be confusing. Markforged have 3 choices in each range and the higher you go up, the more materials you can 3D print with.

The desktop range includes:

The industrial range includes:

Comparison Matrix

This table shows the main differences between a desktop and an industrial 3D printer.

Apart from the bed size and resolution, the main differences are the Adaptive Bed Leveling and In-Process Laser Inspection. These two features use encoders and lasers for higher reliability, accuracy and repeatability. The Industrial range uses lasers to do a 56-point laser check to level the bed and then the printer will print a couple layers then do another laser check and then compensate if required, which ensures a level and accurate foundation to the print.

This video shows the accuracy of the Markforged Desktop and Industrial 3D printers

Would you like Encoders with that?

Encoders are used to validate the position of the print head, so if the print head is instructed to be at a certain coordinate, the encoder will validate the coordinate and correct the stepper if required.

Laser micrometer in action

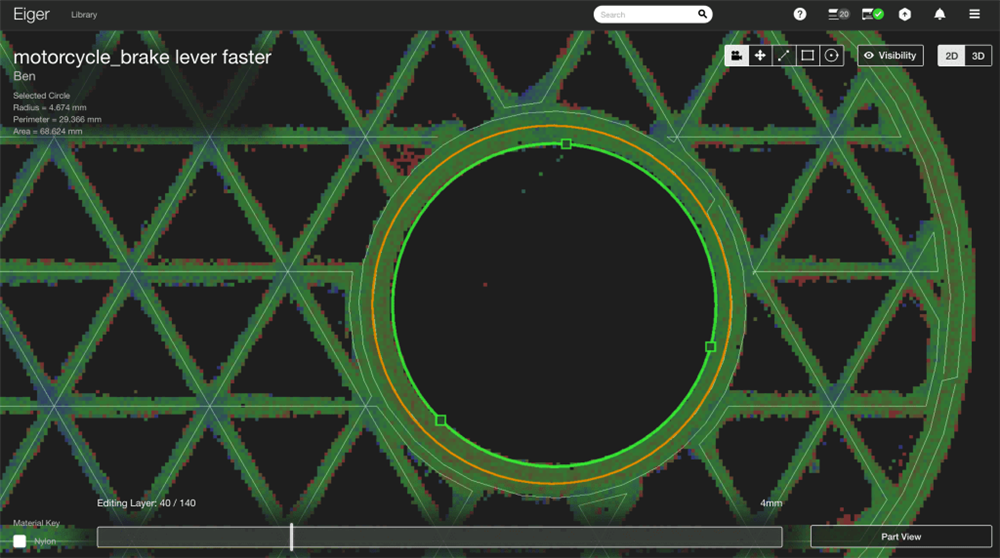

In-Process tolerance validation

The X7 goes one step further and does a laser scan mid-way through the 3D print where you can compare your CAD model and laser scan to ensure repeatability.

Conclusion

The choice depends on your buying criteria. The obvious ones are bed size and resolution, generally, 100 micron is sufficient and who doesn’t want a bigger print volume.

Laser scan of 3D print for tolerance validation

If you need strongest parts, the Mark Two and X7 give you the best choices in continuous fiber (Kevlar, HSHT Fibreglass and Carbon Fibre). If you want 3D prints with tight tolerances, then the Industrial X-Series provides the most accuracy, and if you want to check tolerances before the job is finished, then the in-process laser inspection on the X7 provides has that added feature.

The X7 is the flagship composite product from Markforged with the ability to 3D print base materials in Onyx (Nylon with chopped carbon fibre), Onyx FR (Fire Retardant) and Nylon with more base materials coming. The other unique feature that is soon to be released is Blacksmith, an AI machine learning tool to produce even more accurate parts.

We’ve covered the technical aspects of the Desktop and Industrial 3D printers, but sometimes (or most times!) it all comes down to your budget. The desktop range is priced in the prosumer to a professional level, while the industrial series is a professional grade printer and is priced similar to other high-end 3D printers.